Tel: +86 188 2689 9458

Tel: +86 188 2689 9458

Tel: +86 188 2689 9458

Tel: +86 188 2689 9458

source:Industry News release time:2024-05-17 Hits:

![]() Thermal insulation materials play a vital role in modern engineering and technology. They can effectively reduce the speed of heat transfer, thereby achieving the effects of heat preservation and energy saving in various applications. Understanding the working principles of thermal insulation materials will help us better select the types of thermal insulation materials and develop more efficient construction methods.

Thermal insulation materials play a vital role in modern engineering and technology. They can effectively reduce the speed of heat transfer, thereby achieving the effects of heat preservation and energy saving in various applications. Understanding the working principles of thermal insulation materials will help us better select the types of thermal insulation materials and develop more efficient construction methods.

The working principle of thermal insulation materials is to reduce the efficiency of the three main heat transfer modes of heat conduction, heat radiation and heat convection by using low thermal conductivity materials and pore structures, so as to achieve the purpose of slowing down heat transfer. Let's first understand the three main modes of heat transfer:

Heat Conduction

Thermal conduction is the process of heat transfer from a high-temperature object to a low-temperature object. It is essentially a heat transfer phenomenon caused by the thermal movement of microscopic particles (such as atoms, molecules, etc.) inside the object. The rate of heat conduction is significantly affected by the thermal conductivity of the material. For example: Metals transfer heat quickly due to their high thermal conductivity. In contrast, insulating materials such as wood or plastic have low thermal conductivity and therefore slow the transfer of heat.

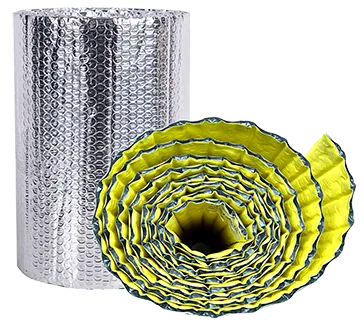

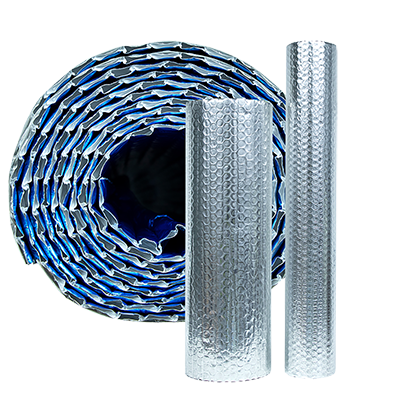

Insulation materials usually have low thermal conductivity, which makes the ability of heat transfer inside them weak. This is mainly due to the molecular structure and composition characteristics of insulation materials. For example, polymer materials and insulating silicate materials have much lower thermal conductivity than high thermal conductivity materials such as metals. In addition, insulation materials often contain air layers, such as fiber gaps in materials such as glass fiber and rock wool, and bubbles in foam plastic materials. These structures can effectively slow down the transfer rate of heat.

Heat radiation

Thermal radiation refers to the phenomenon that an object radiates electromagnetic waves due to its temperature. It is widely present in nature and artificial environments. For example, the radiation of the sun, the radiation of flames, and the infrared radiation of objects are all thermal radiation. All objects above absolute zero can generate thermal radiation, and the higher the temperature, the greater the total energy radiated.

Thermal insulation materials often reflect most of the thermal radiation by coating their surfaces with materials with high reflectivity such as metal or special ceramics, preventing it from entering the interior of the material, thereby maintaining the stability of the internal temperature.

Heat radiation

Thermal convection refers to the process of heat transfer caused by the relative displacement of the fluid parts due to the macroscopic movement of the fluid (liquid or gas), and the mixing of hot and cold fluids. Thermal convection can be forced convection driven by external forces, or it can be natural convection caused by density changes caused by temperature differences.

Insulation materials often use porous structures that can capture and store a lot of air, reducing the possibility of heat convection by reducing air flow. At the same time, some insulation materials use layered structures to effectively hinder the occurrence of heat convection by increasing the path length of heat transfer.

In summary, the working principle of thermal insulation materials involves the delicate regulation of multiple heat transfer methods such as heat conduction, heat radiation and convection. By selecting appropriate materials and designing structures, thermal insulation materials can effectively reduce heat transfer and protect the stability of internal temperature.

https://www.toplinepackaging.com/flexible_packaging_film_roll/#99

Read recommendations:

reusable Snack food bag manufacturer

Retort bags, freeze-resistant vacuum bags

Separate pure aluminum foil bags and aluminum plated bags for you.aluminum foil bag price

Popular recommendation

Spout pouch

Wholesale High Barrier Plastic Stand Up Flat Bottom Pet Dog Food Packaging Bag

3L 5L Bag-In-Box Wine Dispenser Coffee/ Juice/ Water/ Oil Bag-In-Box With Valve

packaging spout pouch Production

coffee pouch design Vendor

clear spout pouch distributors

Aluminum foil bag custom

biodegradable spout pouches price

coffee grinds pouches Processing

spout pouch bag Factory

History and Briefing of Ziplock Pouch

Bag-In-Box: The Future of Flexible Packaging and Its Impact on Top-line Growth

Development Trend of Aluminum Foil Ton Bag Industry.aluminum foil bag large

What is the function of the hole on the coffee bag

Juice Pouch Bags: The Ultimate Guide

Development prospect of packaging bags

Top-line packaging exhibition

Food design graphics analysis.

How to use the air hole on the coffee bag

Introduction to packaging methods for containerized liquids

Food packaging bags that need high temperature characteristics.biodegradable clear mailing bags Manu

The characteristics of the characteristics of all kinds of packaging bags.Flexible packaging film ro

The development trend of domestic food packaging.printed snack food bags distributors

Cooking bag food packaging mainstream products

Toothpaste packaging bag

Specifically talk about the scope of application of aluminum foil bags

Food vacuum packaging bag customized why favor nylon composite film

What are the issues to pay attention to when customizing plastic packaging bags

A major advantage of food grade vacuum packaging bags

Food packaging is closely related to food safety.reusable Snack food bag