Tel: +86 188 2689 9458

Tel: +86 188 2689 9458

Tel: +86 188 2689 9458

Tel: +86 188 2689 9458

source:Industry News release time:2023-10-24 Hits:

Introduction:

In the world of packaging, innovation is key.

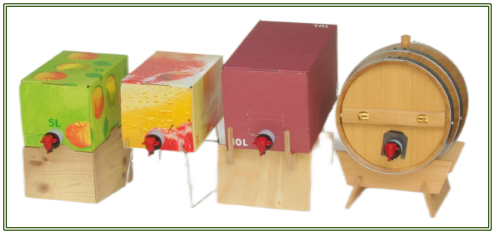

One such innovative solution that has gained significant traction in recent years is the Bag-In-Box packaging. This flexible packaging concept has revolutionized the way liquids such as beverages, sauces, oils, and even laundry detergents are stored, handled, and consumed. With its numerous benefits, Bag-In-Box packaging has become a game-changer for businesses, driving top-line growth while meeting the evolving needs of

The Rise of Bag-In-Box Packaging:

The Rise of Bag-In-Box Packaging:

Bag-In-Box packaging, as the name suggests, comprises a bag that is encased within a rigid outer box.

This combination provides a highly convenient and efficient solution for both manufacturers and consumers. The flexible bag acts as a barrier against oxygen, moisture, and light, ensuring the longevity and quality of the product within. Meanwhile, the outer box provides stability and protection during transportation and storage.

Superior Quality and Extended Shelf Life:

One of the key advantages that Bag-In-Box packaging offers is its ability to extend the shelf life of products. The air-tight design of the flexible bag prevents oxidation, significantly reducing spoilage and maintaining the freshness of the contents. This feature is particularly beneficial for liquids with a shorter shelf life, such as beverages and dairy products, as it minimizes waste and allows for wider distribution.

Convenience and Portability:

The Bag-In-Box format offers unparalleled convenience to consumers. Its lightweight and compact design make it easy to handle, pour, and store, eliminating the need for bulky containers and reducing packaging waste. Moreover, the integrated spout or tap allows for hassle-free dispensing, ensuring minimal product wastage and mess. Whether it is a picnic in the park or camping in the wilderness, Bag-In-Box packaging fits seamlessly into any lifestyle, making it an attractive choice for consumers.

Eco-Friendly Solution:

Sustainability is a growing concern for both businesses and individuals. Bag-In-Box packaging has emerged as a greener alternative to traditional packaging methods. The flexible bag consumes fewer resources during production and transportation, resulting in a reduced carbon footprint. Additionally, Bag-In-Box packaging generates less post-consumer waste compared to glass or rigid plastic bottles, contributing to the overall waste reduction efforts. Many manufacturers now use recyclable materials for Bag-In-Box packaging, further aligning with the global sustainability movement.

Driving Top-Line Growth:

The adoption of Bag-In-Box packaging opens up new opportunities for businesses to drive their top-line growth. The flexible format allows for more efficient inventory management, reducing storage costs and optimizing supply chain logistics. Moreover, the ability to offer larger package sizes, such as 3 or 5-liter bags, caters to the growing demand for bulk purchasing, especially in the foodservice industry.

The adoption of Bag-In-Box packaging opens up new opportunities for businesses to drive their top-line growth. The flexible format allows for more efficient inventory management, reducing storage costs and optimizing supply chain logistics. Moreover, the ability to offer larger package sizes, such as 3 or 5-liter bags, caters to the growing demand for bulk purchasing, especially in the foodservice industry.

Furthermore, Bag-In-Box packaging offers excellent branding opportunities. The outer box acts as a canvas for captivating brand graphics and messaging, enhancing product visibility and consumer engagement. The distinct design also enables manufacturers to differentiate their products from competitors, effectively capturing the attention of the consumers and boosting sales.

Conclusion:

The Bag-In-Box packaging concept has revolutionized the way liquids are packaged, stored, and consumed. Its numerous advantages, including extended shelf life, convenience, eco-friendliness, and branding opportunities, have made it a preferred choice for businesses seeking top-line growth. As consumer preferences continue to evolve, embracing innovative packaging solutions like Bag-In-Box becomes essential for staying ahead in the market. With its promising future, Bag-In-Box packaging is undoubtedly here to stay, shaping the way products are packaged and delivered to the hands of consumers worldwide.

#www.toplinepackaging.com

https://www.toplinepackaging.com/products/Bag-In-Box_288.html

Read recommendations:

125g 250g 500g 1kg Aluminum Foil Flat Bottom Coffee Bean Bags With Valve

packaging spout pouch supplier

Common frozen food packaging materials.smart food Snack food bag

Popular recommendation

Spout pouch

Custom Size Printed Coffee Milk Juice Wine Bib Bag-In-Box With Valve Gift Cardboard Box

Custom Portable Reusable Drink Bags Stand Up Plastic Spout Pouches For Beverages Liquid Packaging

bag in box Processing

wine bag in box custom

Flexible packaging film roll Factory

resealable coffee bags with valve

packaging spout pouch

wine bag in box distributors

smart spout pouch price

Development prospect of packaging bags

The application of vacuum in food packaging and freezing and drying industry

How to distinguish the materials of food packaging bags?

What is the principle of vacuum nozzle? Negative pressure principle

Vacuum packaging bag.food vacuum bag

Can the vacuum bag be reused?

What is the quality of degradable plastic bags?

What equipment is needed to produce plastic packaging bags

Classification of liquid bags

Bag-in-Box with Tap: The Innovative Solution for Efficient Liquid Packaging

Types of packaging bags

Do you have a detailed understanding of paper plastic composite bags?aluminum foil bag roll Manufact

Knowledge of anti-static packaging bag

The printing principle of composite bags!Snack food bag bulk Solution

How to cut food packaging bags?

Tell you the reason for the surface wrinkling of high-temperature cooking bags after sterilization.r

What are the reasons for the delamination of aluminum foil bags.aluminum foil bag large company

What do you need to pay attention to if you use a vacuum packaging bag?mini pet food bag Vendor

Food packaging bags.smart food Snack food bag manufacture

Why choose aluminum foil bags for mask packaging bags