Tel: +86 188 2689 9458

Tel: +86 188 2689 9458

Tel: +86 188 2689 9458

Tel: +86 188 2689 9458

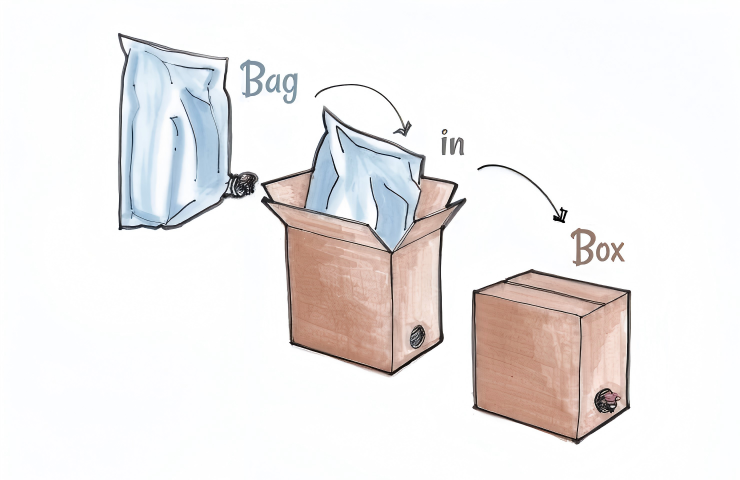

Why Flexible Packaging Is Transforming the Beverage and Liquid Industry Flexible packaging has become a defining innovation in the global liquid and beverage market. From wine and juice to milk, coffee, and edible oils, more brands are replacing rigid containers with bag-in-box (BIB) solutions that offer sustainability, convenience, and excellent product protection. At Top-line Packaging, we specialize in manufacturing and supplying high-performance flexible packaging systems tailored for liquid products. Our bag-in-box series—including wine bag in box, juice bag in box, milk bag in box, oil bag in box, coffee bag in box, syrup bag in box, and sauce bag in box—combine advanced barrier materials, efficient storage, and customizable branding options to meet the demands of modern producers.

Aluminum foil bag packaging usually refers to aluminum plastic composite packaging bag, according to the process structure can be divided into: two-layer co...

In the past two decades, the use of vacuum atmosphere to keep food for fresh packaging technology has developed rapidly. Because this kind of packaging not ...

First, its single grain, forming a lot of micro channels, so that the vacuum without dead Angle. Second, it is 7 layers of co-extrusion, no glue composite....

1. Insufficient heat sealing temperature In general, when the total thickness of the bag is 80~90 μ M, the heat sealing temperature shall reach 170~180 ℃; ...

The main function of vacuum packaging bag is to remove oxygen to help prevent food deterioration. Its principle is also relatively simple. Because food mild...

Packing bag sealing brittle and brittle break reason: (1) The heat seal temperature is too high. (2) Too much pressure. (3) The heat sealing time is too ...